- Primary Shredders

- VB 450

- VB 650

- VB 750

- VB 850

- VB 950

[rev_slider alias="carousel-vb450"]

HAMMEL primary shredder VB 450 |

|||

| Applications: | |||

| Wood | waste wood, demolition wood, root stems, green waste, pallets, cable drums | ||

| Waste | domestic waste, C&I waste | ||

| Technical Data* | VB 450 D |

VB 450 DK |

VB 450 E  |

| Version | Hooklift | Chain | Electrical |

| Engine | CAT C4.4 | Cummins F3.8 - Stage 5 | - |

| Drive Train | 145 PS | 145 PS | 110 KW |

| Weight | 8 t machine + 1 t magnet | 9 t machine + 1 t magnet | 8 t machine + 1 t magnet |

Primary Shredders Primary Shredders6 MB | |||

| Functional principle | hydraulically operating recycling machine with two slow-moving shafts | ||

| Advantages |

|

||

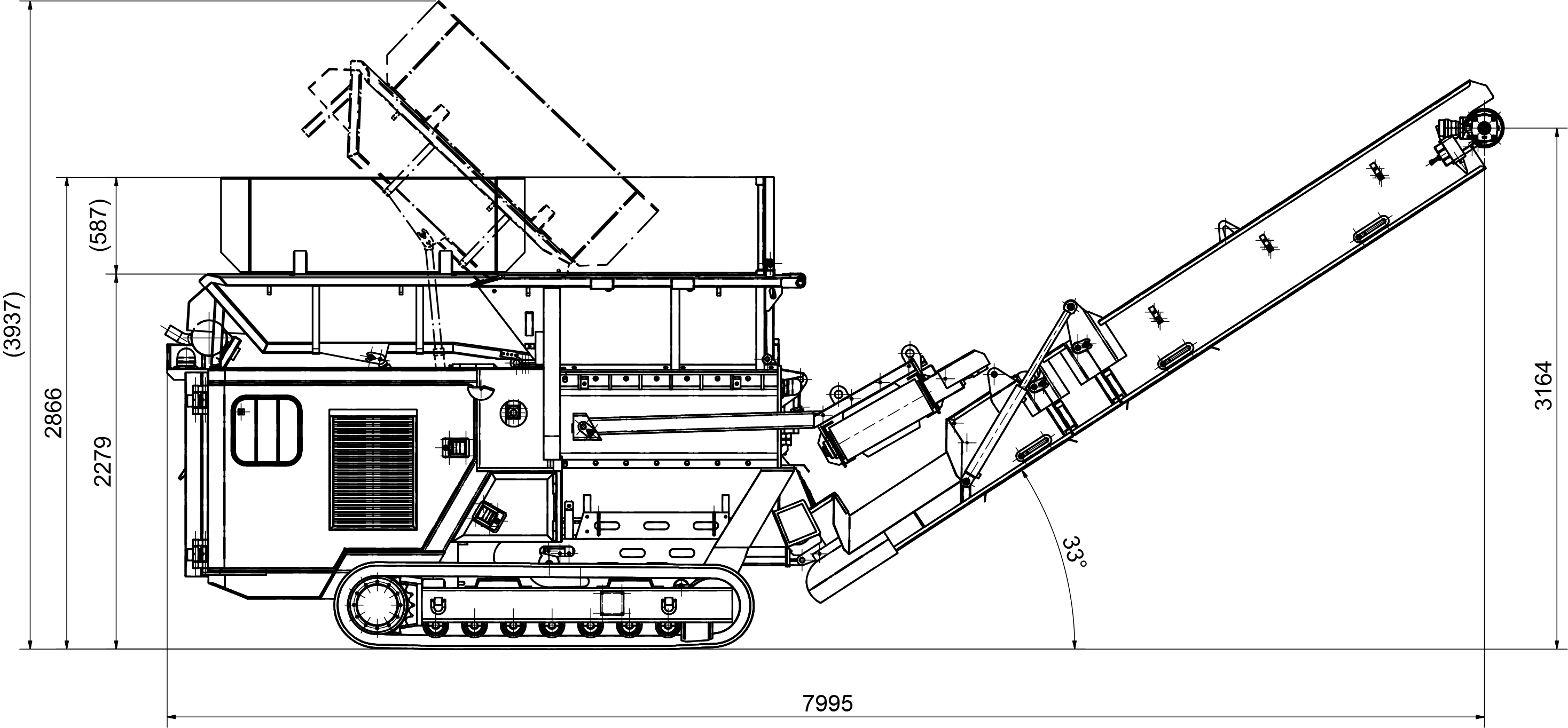

| Technical DrawingVB 450 DK (Dimensions in mm) |

|

||

*approx. values; subject to change

[rev_slider alias="carousel-vb650"]

HAMMEL primary shredder VB 650 |

|||

| Applications | |||

| Wood | waste wood, demolition wood, root stems, green waste, railway sleeper, pallets, cable drums | ||

| Waste | domestic waste, C&I waste | ||

| Miscellaneous | paper, paper rolls | ||

| Technical Data* | VB 650 D |

VB 650 DK |

VB 650 E  |

| Version | Hooklift | Chain | Electrical |

| Engine | Cummins B6.7 - Stage 5 | Cummins B6.7 - Stage 5 | - |

| Drive Train | 280 PS | 280 PS | 200 KW |

| Weight | 16 t machine + 2 t magnet | 18 t machine + 2 t magnet | 16 t machine + 2 t magnet |

Primary Shredders Primary Shredders6 MB |

|||

| Functional principle | hydraulically operating recycling machine with two slow-moving shafts | ||

| Advantages |

|

||

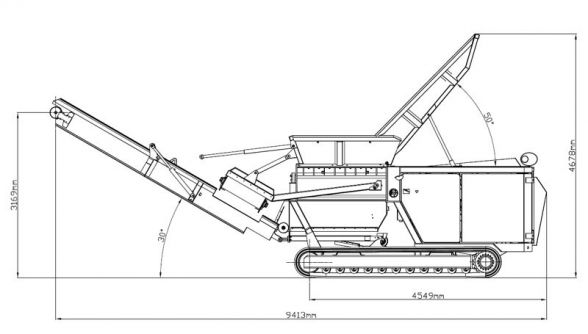

| Technical DrawingVB 650 DK (Dimensions in mm) |

|

||

*approx. values; subject to change

[rev_slider alias="carousel-vb750"]

HAMMEL primary shredder 750 |

|||

| Applications | |||

| Wood | waste wood, demolition wood, root stems, green waste, railway sleeper, pallets, cable drums | ||

| Technical data* | VB 750 D |

VB 750 DK L.V. |

VB 750 E |

| Version | Hooklift | Chain | Electrical |

| Engine | CAT C9.3 - Stage 5 | CAT C9.3 - Stage 5 | - |

| Drive Train | 380 PS | 380 PS | 2 x 132 kW |

| Weight | 19 t machine + 2 t magnet | 22.5 t machine + 1 t magnet | 20 t machine + 2 t magnet |

Primary Shredders Primary Shredders6 MB |

DK Datenblatt DK Datenblatt6 MB |

||

| Functional principle | hydraulically operating recycling machine with two slow-moving shafts | ||

| Advantages |

|

||

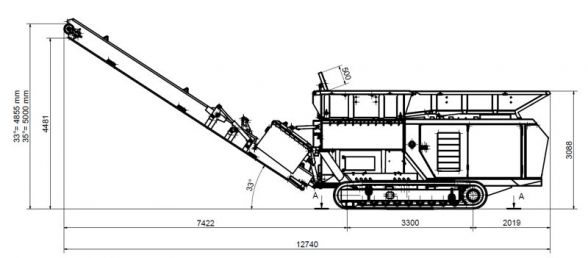

| Technical Drawing VB 750 DK L.V. (Dimensions in mm) |

|

||

*approx. values; subject to change

[rev_slider alias="carousel-vb850"]

HAMMEL primary shredder VB 850 |

|||

| Applications | |||

| Wood | waste wood, demolition wood, root stems, green waste, railway sleeper, pallets, cable drums | ||

| Waste | domestic waste, C&I waste, bulky waste, demolition waste, tires | ||

| Metal | aluminum profiles and bales | ||

| Miscellaneous | paper, paper rolls | ||

| Technical data* | VB 850 D(only on demand) | VB 850 DK |

VB 850 E

|

| Version | Hooklift | Chain | Electrical |

| Motor | Cummins X 12 - Stage 5 | Cummins X 12 - Stage 5 | - |

| Drive Train | 450 PS | 450 PS | 320 KW |

| Weight | 27 t | 35 t machine + 3 t magnet | 30 t machine + 3 t magnet |

Primary Shredders Primary Shredders6 MB |

|||

| Functional principle | hydraulically operating recycling machine with two slow-moving shafts | ||

| Advantages |

|

||

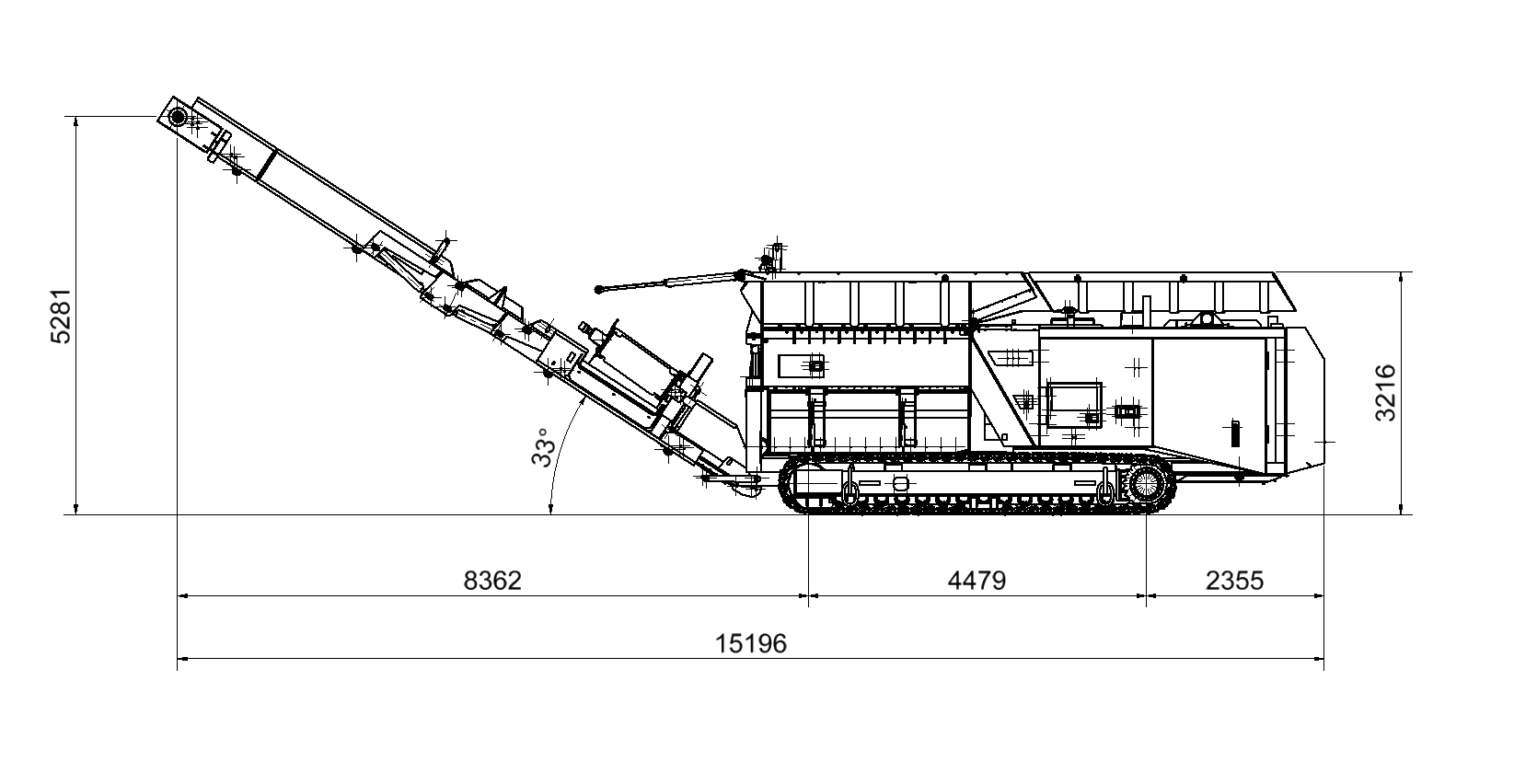

| Technical DrawingVB 850 DK (Dimensions in mm) |

|

||

*approx. values; subject to change

[rev_slider alias="carousel-vb950"]

HAMMEL primary shredder VB 950 |

|||

| Applications | |||

| Wood | waste wood, demolition wood, root stems, green waste, railway sleeper, pallets, cable drums | ||

| Waste | domestic waste, C&I waste, bulky waste, demolition waste, tires | ||

| Metal | aluminum profiles and bales | ||

| Miscellaneous | paper, paper rolls | ||

| Technical data* | VB 950 DK |

VB 950 E |

|

| Version | Chain | Electrical | |

| Engine | CAT C18 - Stage 5 | - | |

| Drive Train | 760 PS | 2x250 KW | |

| Weight | 44 t machine + 3 t magnet | 38 t machine + 3 t magnet | |

Primary Shredders Primary Shredders6 MB |

|||

| Functional priciple |

|

||

| Advantages |

|

||

| Technical DrawingVB 950 DK (Dimensions in mm) |

|

||

*approx. values; subject to change

English (UK)

English (UK)  Deutsch

Deutsch  Español

Español  Français

Français  Italiano

Italiano